1. Stable, easy control, a wide range of concentration;

2. Large capacity, enrichment ratio, high recovery rate;

3. Small cover space, less water consumption, simple structure design, no need for power;

4. Simple installation, convenient operation,less investment, quick return;

5. Stable and clear mineral separation with large handling capacity;

6. High efficiency with higher concentration ratio;

7. High adaptability of feeding capacity and the variability of concentration, granularity and grade;

8. Material quality with features of moisture resistance, rust protection and corrosion resistance;

9. With advantages of non-powered, without moving parts and without noise, etc.

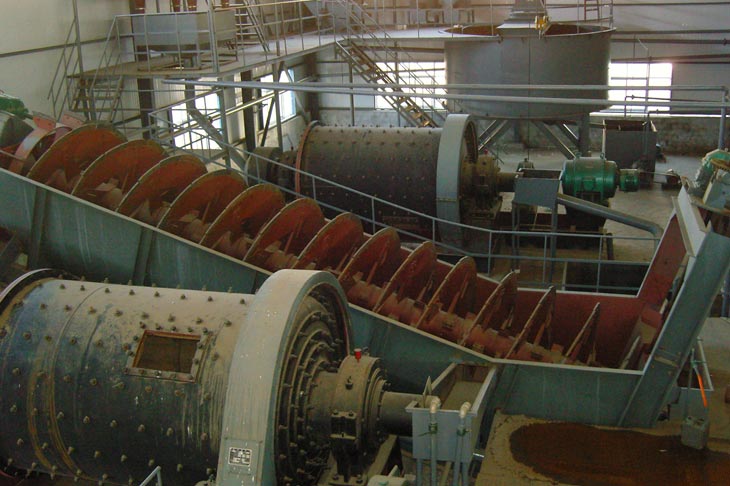

Ore pulps are uniformly fed into the machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones concentrate, middling and tailing.

Spiral chute is suitable for the treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

| Model |

LL-2000 |

LL-1500 |

LL-1200 |

LL-900 |

LL-600 |

| External Diameter(mm) |

2000 |

1500 |

1200 |

900 |

600 |

| Pitch(mm) |

1200 |

720, 540 |

720, 540 |

540, 405 |

450, 360 |

| Cross Dip(°) |

9° |

9° |

9° |

9° |

9° |

| Spiral Quantity |

1-3 |

1-4 |

1-4 |

1-4 |

1-3 |

| Max turns of Spiral |

4 |

5 |

5 |

5 |

5 |

| Feed Size(mm) |

4-0.04 |

0.8-0.037 |

0.3-0.03 |

0.3-0.03 |

0.2-0.02 |

| Feed Density (%) |

20-45 |

25-50 |

25-55 |

25-55 |

25-55 |

| Capacity(t/h) |

15-40 |

6-8 |

4-6 |

2-3 |

0.8-1.2 |

| Overall Dimension |

Length(mm) |

2300 |

1560 |

1360 |

1060 |

700 |

| |

Width(mm) |

2300 |

1560 |

1360 |

1060 |

700 |

| |

Height(mm) |

6500 |

5230, 4360 |

5230, 4360 |

4000, 3325 |

2600, 2150 |

| Weight(kg) |

1350 |

800 |

600 |

400 |

150 |