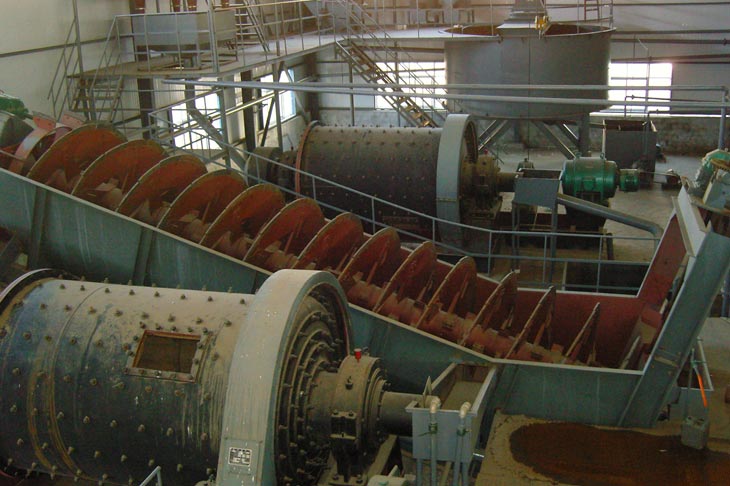

1. Jack-up device, easy maintenance;

2. The hydrostatic and hydrodynamic bearings ensure the smooth operation;

3. Low-speed transmission is easy for starting and maintenance;

4. The oil-mist lubrication device guarantees reliable performance of bearings;

5. The gas clutch adopts the flexible start-up model;

6. According to the customer demand, manganese steel liner and wear-resistant rubber liner can be customized for Xinhai ball mill, with good wear resistance, long service life, easy maintenance.

Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportion. Driven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in the cylinder. Due to the continuously feeding materials, the pressure pushes materials to the outlet and the ground materials are discharged from the cylinder outlet. Qualified materials flow from the cylinder outlet. In wet grinding, the materials are taken out by the water flow. There are back pitch impellers in the hollow shaft, which can make the balls and coarse ores in the overflow return to the mill. With simple structure, higher operation rate, and rolling bearing, energy conservation is significant.

Generally used in the grinding of ores with finer fineness.

| Model |

Standards |

Motor model |

Motor power

(kw) |

Rotating speed of cylinder

(r/min) |

L

(mm) |

W(mm) |

H

(mm) |

Effective volume

(m³) |

Max load

of balls

(t) |

Weight

(kg) |

Capacity

(t/h) |

| MQY0918 |

Φ900*1800 |

Y225M-8 |

22 |

41.6 |

5080 |

2300 |

2015 |

0.9 |

1.66 |

6078 |

0.37-1.8 |

| MQY1212 |

Φ1200*1200 |

Y250M-8 |

30 |

34.8 |

5023 |

2794 |

2540 |

1.14 |

2.4 |

11473 |

0.2-4.1 |

| MQY1224 |

Φ1200*2400 |

YR280S-8 |

55 |

34.8 |

6112 |

2794 |

2540 |

2.28 |

3.8 |

12308 |

0.35-8.2 |

| MQY1515 |

Φ1500*1500 |

JR115-8 |

60 |

30.7 |

5766 |

2945 |

2600 |

2.2 |

6.4 |

15424 |

1.4-5 |

| MQY1530 |

Φ1500*3000 |

JR125-8 |

95 |

30.7 |

7979 |

2945 |

2600 |

4.5 |

10 |

18690 |

2.5-8 |

| MQY1830 |

Φ1800*3000 |

JR127-8 |

130 |

25.04 |

9525 |

3960 |

2250 |

7.5 |

13 |

29490 |

3~17 |

| MQY1834 |

Φ1800*3400 |

JR128-8 |

155 |

25.04 |

9925 |

3960 |

2250 |

8.5 |

14 |

30390 |

3.3~20 |

| MQY1836 |

Φ1800*3600 |

JR128-8 |

155 |

25.04 |

10125 |

3960 |

2250 |

9 |

15 |

31600 |

4~21.5 |

| MQY1840 |

Φ1800*4000 |

JR128-8 |

155 |

25.04 |

10525 |

3960 |

2250 |

10 |

17 |

32700 |

4.5~24 |

| MQY1842 |

Φ1800*4200 |

JR136-8 |

180 |

25.04 |

10725 |

3960 |

2250 |

10.5 |

18 |

33490 |

5~25 |

| MQY1844 |

Φ1800*4400 |

JR136-8 |

180 |

25.04 |

10925 |

3960 |

2250 |

11 |

19 |

34210 |

5.2~26 |

| MQY1852 |

Φ1800*5200 |

JR136-8 |

180 |

25.04 |

11725 |

3960 |

2250 |

12 |

21 |

37715 |

6.5~32.5 |

| MQY1864 |

Φ1800*6400 |

JR137-8 |

210 |

25.04 |

12925 |

3960 |

2250 |

14.5 |

27 |

42440 |

8~40 |

| MQY2122 |

Φ2100*2200 |

JR128-8 |

155 |

23.8 |

8070 |

4840 |

3795 |

6.6 |

14 |

47800 |

4.5-26 |

| MQY2130 |

Φ2100*3000 |

JR137-8 |

210 |

23.8 |

8870 |

4840 |

3795 |

9 |

20 |

49780 |

4-30 |

| MQY2136 |

Φ2100*3600 |

JR137-8 |

210 |

23.8 |

9300 |

4840 |

3795 |

10.8 |

22 |

52010 |

4.8-36 |

| MQY2145 |

Φ2100*4500 |

JR148-8 |

310 |

21.7 |

11029 |

4737 |

3300 |

13.5 |

23.8 |

58305 |

8-35 |

| MQY2430 |

Φ2400*3000 |

JR1410-8 |

280 |

21.7 |

9710 |

4778 |

4120 |

12.1 |

23 |

65880 |

6.2-77.6 |

| MQY2721 |

Φ2700*2100 |

JR1410-8 |

280 |

21.7 |

9400 |

5600 |

4700 |

10.7 |

24 |

63900 |

7-78 |

| MQY2736 |

Φ2700*3600 |

TDMK400-32 |

400 |

18.7 |

11400 |

5700 |

4500 |

18.4 |

38 |

70000 |

10.5-130 |

| MQY2740 |

Φ2700*4000 |

TDMK400-32 |

400 |

18.7 |

11850 |

5667 |

4496 |

20.4 |

40 |

78800 |

12-145 |

| MQY3231 |

Φ3200*3100 |

TDMK630-36 |

630 |

18.7 |

12750 |

6760 |

5150 |

21.4 |

45 |

107660 |

74-86 |

| MQY3245 |

Φ3200*4500 |

TDMK630-36 |

630 |

18.7 |

14600 |

6760 |

5200 |

31 |

61 |

112000 |

86-100 |

| MQY3254 |

Φ3200*5400 |

TM1000-

36/2600 |

1000 |

17.3 |

15800 |

6760 |

5200 |

37.2 |

73 |

121000 |

112-135 |

| MQY3645 |

Φ3600*4500 |

TM1000-

36/2600 |

1000 |

17.3 |

15000 |

7200 |

6326 |

41.8 |

76 |

135000 |

170 |

| MQY3650 |

Φ3600*5000 |

TM11250-

40/3250 |

1250 |

17.3 |

17157 |

7755 |

6326 |

46.4 |

86 |

145000 |

40-178 |

| MQY3660 |

Φ3600*6000 |

TM11250-

40/3250 |

1250 |

17.3 |

19000 |

7755 |

6326 |

55.7 |

102 |

154000 |

186 |