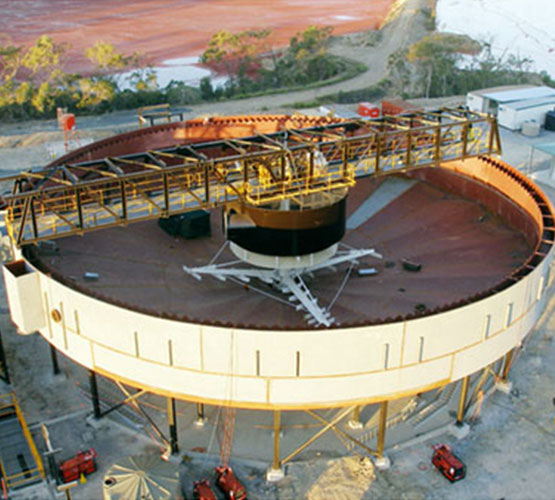

CTB Magnetic Separator

【Introduction】: A wet permanent magnetic separator for separating strong magnetic minerals

【Capacity 】: 8-240t/h

【Improvement】: Magnetic system materials adopt ferrite and NdFeB with high performance, high coercive force and high remanence; the surface of the cylinder is lined with wear-resistant rubber.

CTB magnetic separator is a wet type weak magnetic field permanent magnetic separator with cylinder type. It has the following advantages: energy saving, high magnetic induction intensity, simple structure, low price, easy operation and maintenance, small floor space required and large processing capacity etc. There are three kinds of tank structure: downflow, counterflow, and semi-counter flow, with a separation grain size of 6-0,0.6-0,1-0mm respectively.