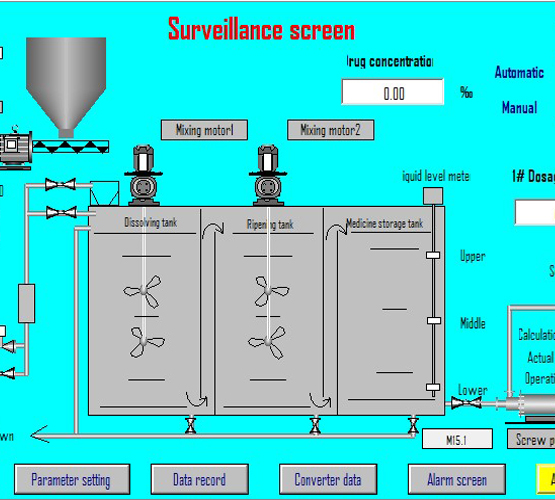

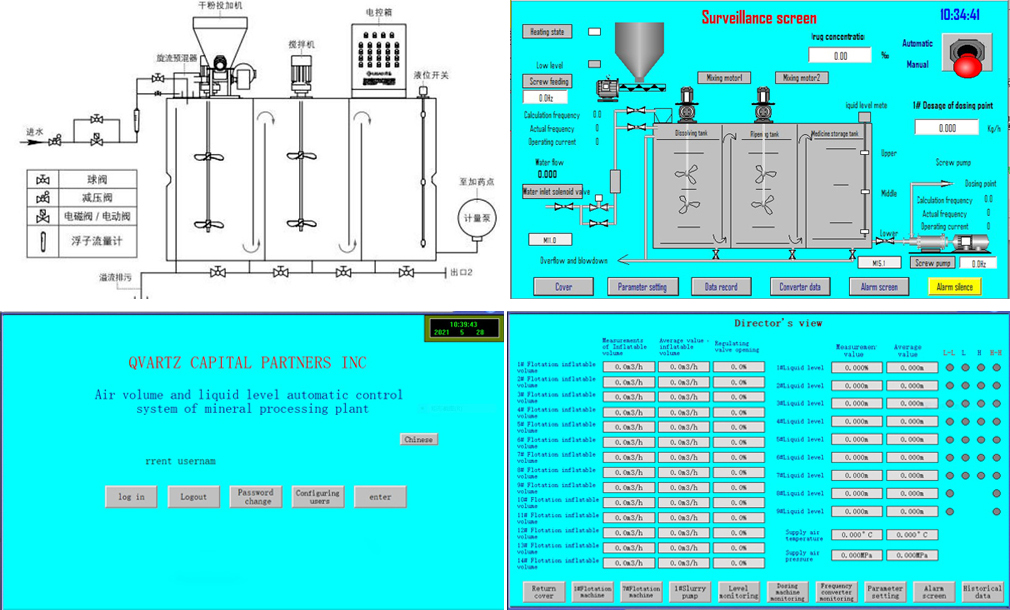

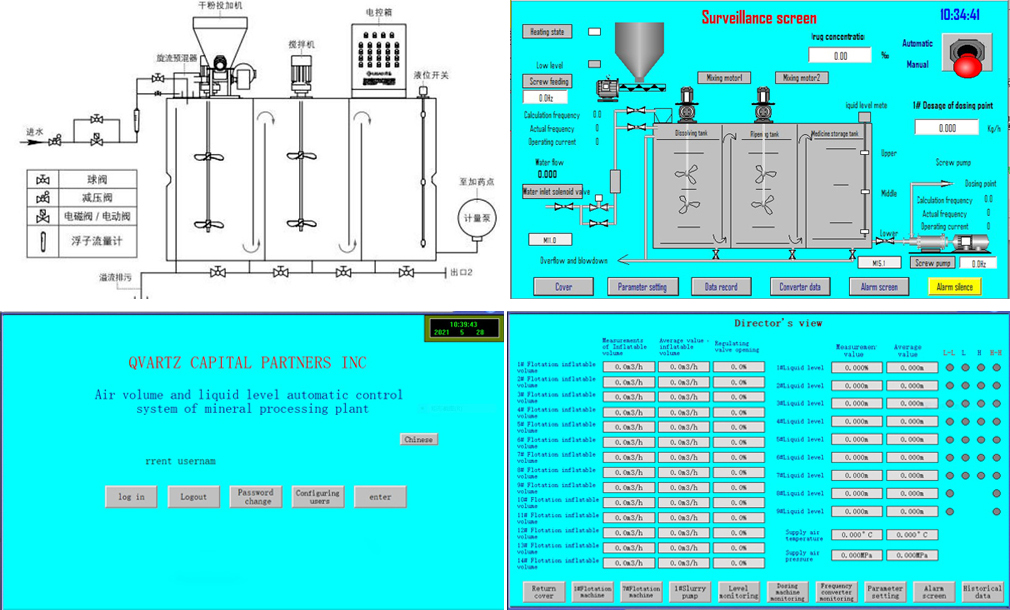

Dry powder enters mixer from the funnel and is diluted by spiral premixer in mixing tank to get solution with required concentration.

The solution flows into maturation tank and then goes into storage tank. When the solution is at low liquid level, level sensor triggers level switch signal, starting device to opearte solution preparation process again. Dosing machine calculates and adjusts reagent dosage based on the required solution concentration by controller. When the solution is at high liquid level, process autostops.In this way, the system can run continuously and the mixer continuously stirs the dry powder.

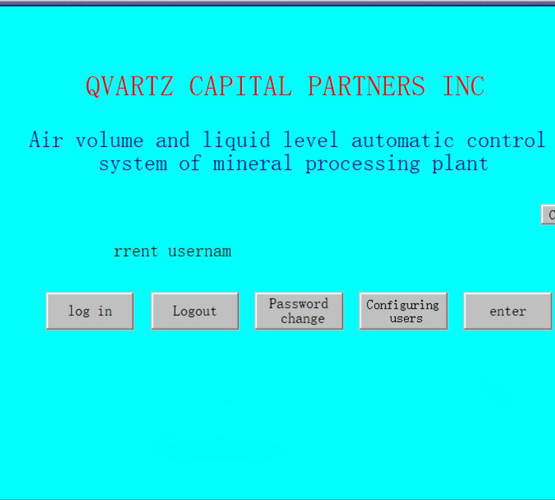

(1). Automatic & easy operation, saving labour;

(2). Reagent dosage can be adjusted precisely to ensure treatment effect and avoid waste;

(3). Continuous production can ensure maturation time and configuration concentration is 0.05%-0.3%. Reagent dissolving effect is 100%;

(4). All stainless steel shell, anti-corrosion & beautiful appearance;

(5). Equipped with imported membrane dosing pump. Modular supply and easy to install;

(6). Rhyther has a professional & reliable team with our customers.