Peripheral Rack Gear Type Thickener

【Introduction】: An independently developed PERIPHERAL RACK GEAR TYPE THICKENER, the underflow concentration up to 70%.

【 Capacity 】: 60~880m3/h.

【Improvement】: Large angle cone, the high underflow concentration.

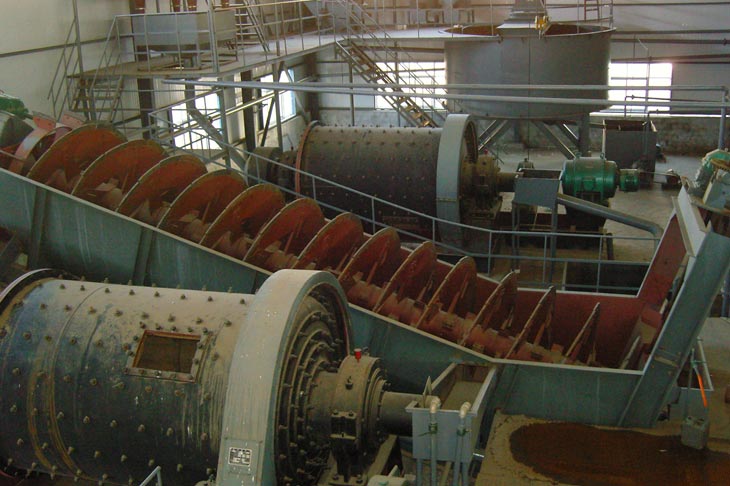

Peripheral transmission thickener has two kinds, peripheral roller transmission and peripheral gear transmission.

This thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. The slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside.

The machine is suitable for dealing with large capacity and light density products. Mainly used for condensing concentrate and dewatering the tailings. It can be also used for condensing and cleaning the pulp with solid particles in coal, chemical, building materials and sewage treatment system.