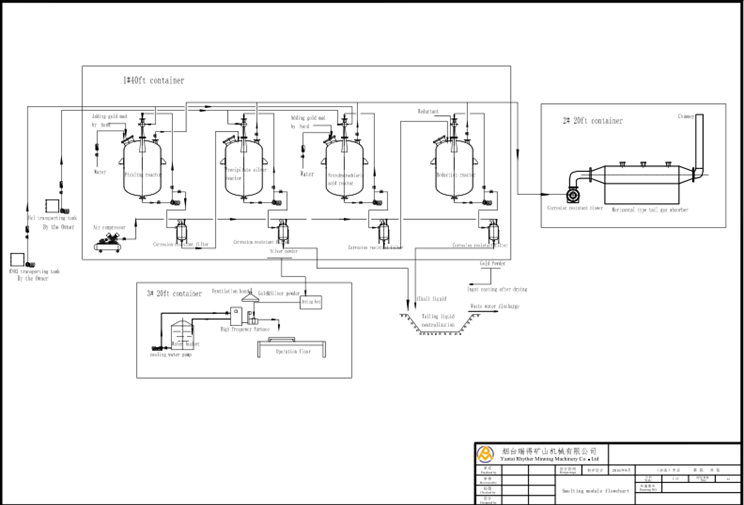

Purification&Smelting System

It is specially designed for processing the gold-silver alloy slime from desorption electrolytic system, Merrill-crow processing system or lower grade gold or silver alloy.

It can separate the gold and silver, improve the gold and silver purity and smelt them into gold ore silver more.

Work together with desorption electrolytic system, Merrill-crow processing system from the Heap leaching, CIL or CIP leaching, vat leaching project or flotation concentrates smelting project.