Merril-Crow Processing System

Process the gold & silver ore concentrates or pregnant solution with low content of Arsenic ( As), Copper (Cu), Carbon ( C ) and Antimony ( Sb) into gold and silver powder.

Gold & silver flotation concentrates regrinding and CIL leaching and smelts it into gold & silver mud to replace the desorption & electrolytic system.

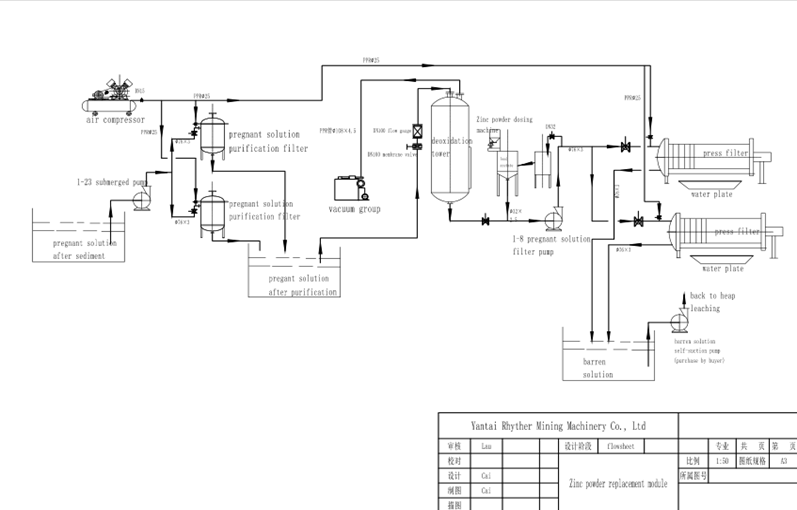

Heap leaching, CIL or CIP leaching and vat leaching pregnant solution processing into gold & silver mud to replace the desorption & electrolytic system.