Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding .It has advantages of fineness uniformity and power saving. The machine uses different types of liner to meet different customer needs. The grinding fineness of material can be controlled by grinding time. The electro-hydraulic machine is auto-coupled and decompressed to reduce the starting current, and its structure is divided into integral type and independent type.

Compared with similar products,Wet Grid ball mill has the characteristics of low investment, low energy consumption, novel structure, simple operation, stable and reliable performance. It is suitable for mixing and grinding ordinary and special materials. The users can choose the right type, liner and medium type by considering the specific gravity, hardness, yield and other factors. The grinding medium is Wet Grid ball.

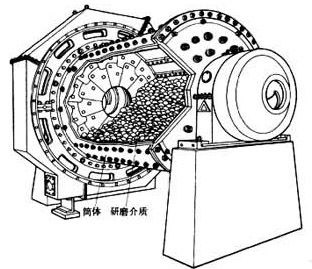

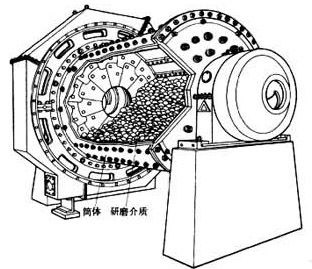

1.The ball mill is composed of a horizontal cylinder, a hollow shaft for feeding and discharging, and a grinding head. The main body is a long cylinder made of steel. The cylinder is provided with an abrasive body, and the steel lining plate is fixed to the cylinder body. The grinding body is generally a steel ball and is loaded into the cylinder according to different diameters and a certain proportion, and the grinding body can also be used with a steel section.

2.According to the particle size of the grinding material, the material is loaded into the cylinder by the hollow shaft of the wet grid ball mill feeding end. When the ball mill cylinder rotates, the grinding body acts on the cylinder liner due to the action of inertia and centrifugal force and friction. It is carried away by the cylinder. When it is brought to a certain height, it is thrown off due to its own gravity. The falling abrasive body crushes the material in the cylinder like a projectile.

3.The material is uniformly fed into the first chamber of the mill by the feeding device through the hollow shaft of the feeding material. The chamber has a step liner or a corrugated liner, and various steel balls are loaded therein. The rotation of the cylinder generates centrifugal force to bring the steel ball to a certain extent. The height drops and then hits and grinds the material. After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition plate. The bin is embedded with a flat liner with steel balls inside to further grind the material. The powder is discharged through the discharge raft to complete the grinding operation.

(1)Steel ball

The main function of the steel ball in the ball mill is to impact crush the material and also play a certain grinding effect. Therefore, the purpose of grading steel balls is to meet the requirements of these two aspects. The quality of the crushing effect directly affects the grinding efficiency, and ultimately affects the output of the ball mill. Whether the crushing requirement can be achieved depends on whether the grading of the steel ball is reasonable, mainly including the size of the steel ball, the number of ball diameters, and the ball of various specifications. Proportion and so on.

(2)Mechanical structure

The ball mill is composed of the main part such as a feeding part, a discharging part, a turning part, a transmission part (a reduction gear, a small transmission gear, a motor, and electric control). The hollow shaft is made of cast steel, the inner lining can be replaced, the rotary large gear is processed by casting hobbing, and the barrel is embedded with wear-resistant lining, which has good wear resistance. The machine runs smoothly and works reliably.

| Model |

Standards |

Motor model |

Motor power

(kw) |

Rotating speed of cylinder

(r/min) |

L

(mm) |

W(mm) |

H

(mm) |

Effective volume

(m³) |

Max load

of balls

(t) |

Weight

(kg) |

Capacity

(t/h) |

| MQG0909 |

Φ900*900 |

Y225S-6 |

15 |

41.6 |

3600 |

1800 |

1400 |

0.45 |

0.96 |

4620 |

0.22~1.07 |

| MQG0918 |

Φ900*1800 |

Y225M-6 |

18.5 |

41.6 |

4700 |

1880 |

1400 |

0.9 |

1.92 |

5340 |

0.4-3.4 |

| MQG1212 |

Φ1200*1200 |

Y250M-8 |

30 |

35.1 |

4400 |

2200 |

1650 |

1.14 |

2.4 |

11438 |

0.17~4.1 |

| MQG1224 |

Φ1200*2400 |

Y315S-8 |

55 |

35.1 |

5600 |

2250 |

1650 |

2.28 |

3.96 |

13200 |

0.35~8.2 |

| MQG1515 |

Φ1500*1500 |

JR115-8 |

60 |

30.7 |

6050 |

2900 |

2030 |

2.2 |

5 |

13700 |

1.4~4.5 |

| MQG1530 |

Φ1500*3000 |

JR125-8 |

95 |

30.7 |

7550 |

2920 |

2030 |

4.5 |

8.4 |

18690 |

2.8~9 |

| MQG1830 |

Φ1800*3000 |

JR127-8 |

130 |

25.04 |

9525 |

3960 |

2250 |

7.5 |

13 |

29490 |

3~17 |

| MQG1834 |

Φ1800*3400 |

JR128-8 |

155 |

25.04 |

9925 |

3960 |

2250 |

8.5 |

14 |

30390 |

3.3~20 |

| MQG1836 |

Φ1800*3600 |

JR128-8 |

155 |

25.04 |

10125 |

3960 |

2250 |

9 |

15 |

31600 |

4~21.5 |

| MQG1840 |

Φ1800*4000 |

JR128-8 |

155 |

25.04 |

10525 |

3960 |

2250 |

10 |

17 |

32700 |

4.5~24 |

| MQG1842 |

Φ1800*4200 |

JR136-8 |

180 |

25.04 |

10725 |

3960 |

2250 |

10.5 |

18 |

33490 |

5~25 |

| MQG1844 |

Φ1800*4400 |

JR136-8 |

180 |

25.04 |

10925 |

3960 |

2250 |

11 |

19 |

34210 |

5.2~26 |

| MQG1852 |

Φ1800*5200 |

JR136-8 |

180 |

25.04 |

11725 |

3960 |

2250 |

12 |

21 |

37715 |

6.5~32.5 |

| MQG1864 |

Φ1800*6400 |

JR137-8 |

210 |

25.04 |

12925 |

3960 |

2250 |

14.5 |

27 |

42440 |

8~40 |

| MQG2122 |

Φ2100*2200 |

JR128-8 |

155 |

23.8 |

7750 |

4050 |

2950 |

6.6 |

15 |

45400 |

5~29 |

| MQG2130 |

Φ2100*3000 |

JR137-8 |

210 |

23.8 |

8970 |

4100 |

2950 |

9 |

20 |

50600 |

6.5~3.6 |

| MQG2430 |

Φ2400*3000 |

JR1410-8 |

280 |

23.8 |

8820 |

4250 |

3670 |

12.1 |

22.5 |

67000 |

9~50 |

| MQG2721 |

Φ2700*2100 |

JR1410-8 |

280 |

21.7 |

9300 |

5500 |

4500 |

10.7 |

24 |

63000 |

6.5~84 |

| MQG2727 |

Φ2700*2700 |

JR148-6 |

320 |

21.7 |

9900 |

5500 |

4500 |

13.8 |

29 |

68530 |

8~100 |

| MQG2736 |

Φ2700*3600 |

TDMK400-

32/2150 |

400 |

21.7 |

9785 |

5767 |

4995 |

18.4 |

41 |

77000 |

12~145 |

| MQG3230 |

Φ3200*3000 |

TDMK500-36 |

500 |

18.7 |

13700 |

6760 |

5100 |

20.7 |

46 |

113500 |

63~73 |

| MQG3231 |

Φ3200*3100 |

TDMK630-36 |

630 |

18.7 |

12750 |

6750 |

5150 |

21.4 |

45 |

114435 |

65~76 |

| MQG3236 |

Φ3200*3600 |

TDMK630-36 |

630 |

18.7 |

14300 |

6760 |

5200 |

24.8 |

58 |

119012 |

74~86 |

| MQG3245 |

Φ3200*4500 |

TDMK800-36 |

800 |

18.7 |

12700 |

7200 |

5700 |

31 |

65 |

127650 |

95~110 |

| MQG3639 |

Φ3600*3900 |

TM1000-

36/3600 |

1000 |

17.3 |

15000 |

7200 |

6300 |

36.2 |

75 |

145000 |

34~187 |

| MQG3645 |

Φ3600*4500 |

TDMK1250-40 |

1250 |

17.3 |

15200 |

7750 |

6300 |

41.8 |

90 |

159700 |

38~210 |

| MQG3650 |

Φ3600*5000 |

JM1400-40 |

1400 |

17.3 |

17600 |

7750 |

6300 |

46.4 |

96 |

158000 |

192 |

| MQG3660 |

Φ3600*6000 |

TDMK1600-40 |

1600 |

17.3 |

17000 |

8800 |

6500 |

55.7 |

120 |

189000 |

230 |