Wet Pan Mill

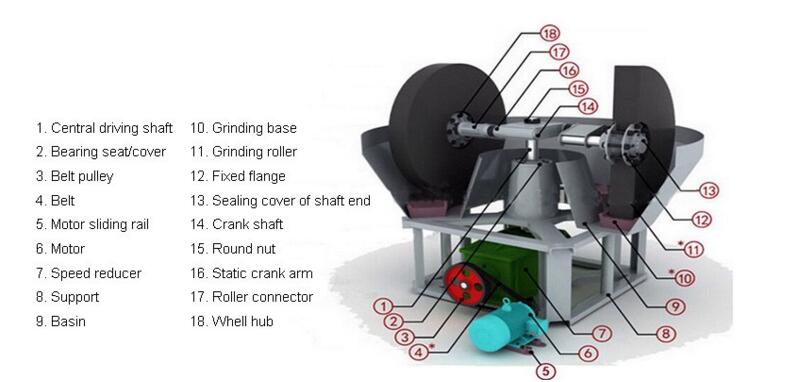

Wet Pan Mill is also called Wet Grinding Machine. Based on the different structure it is divided into double roller grinding and three roller grinding. Wet pan mill mainly used for grinding operation, such as all kinds of ferrous metal, non-ferrous metal, non-metallic minerals, and the separation of gold, silver, lead, iron, copper-gold and so on.

The Wet Pan Mill is a new mill, small investment, high yield, the production cost is low, good benefits. The wet pan mill is named by the diameter of the roller. 1300, 1350, 1400, 1500,1600 is suitable for selection of iron ore, molybdenum ore, lead ore, zinc ore, antimony ore and so on. 850, 900, 1000, 1100, 1200 is suitable for selection of gold ore.

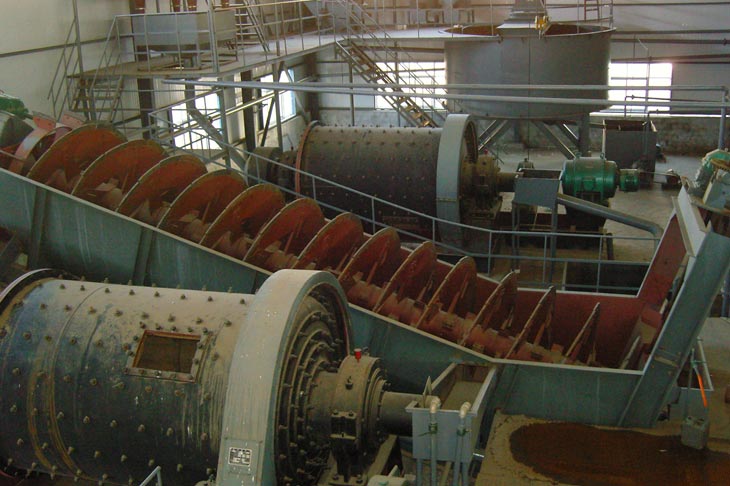

Our gold grinding Wet Pan Mill is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected. With less investment, fast results, small footprint saving power, sturdiness and durability, ease of maintenance and high return on investment. It is the preferred production for alternative ball mill, is ideal for small and medium enterprises dressing.