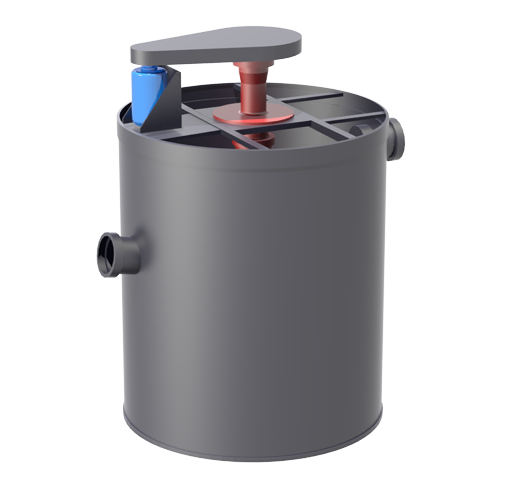

Double Impeller Leaching Tank

【Introduction】: Leaching agitation tank is a leaching equipment for cyanide leaching by referring to the USA technical design.

【Volume】: 6-395m3

【Improvement】: Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform inflation.

This double impeller leaching and the agitating tank is used in carbon paste flow and cyanidation process. The carbon-immersing tank should match other auxiliary devices like Carbon-separating Screen, and recessed impeller pump etc.